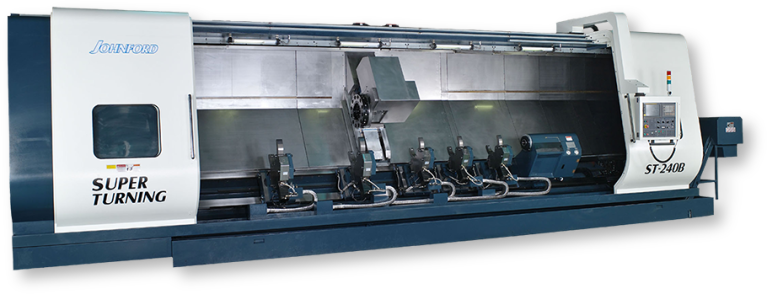

ST車銑複合系列

- High performance cutting capabilities in turning, milling and even both together in one single set-up.

- 0.001° B-axis with 6000 rpm milling/turning spindle for 4+1-axis or simultaneous 5-axis machining.

- 60° slant-bed design for optimum chip removal rate.

- Most rigid box ways on all axes.

- Enormous cutting diameter up to Ø1000mm or above.

Please scroll left and right for full information

| ITEM / MODEL | ST-60CX+B+C+Y | ST-160FX+B+C+Y | ST-400BX+B+C+Y | ST-80CX+B+C+Y | ST-130EX+B+C+Y | ST-160BX+B+C+Y | |

|---|---|---|---|---|---|---|---|

| Cutting Capacity - Max. swing over bed (mm) | Ø1200 | Ø1200 | Ø1200 | Ø1200 | Ø1200 | Ø1200 | |

| Cutting Capacity - Max. turning diameter (mm) | Ø800 | Ø800 | Ø350 | Ø850 | Ø850 | Ø800 | |

| Cutting Capacity - Distance between centers (mm) | 1200 | 4000 | 10000 | 2000 | 3050 | 4000 | |

| Cutting Capacity - Chuck size (mm) | 510 (20”) | Front: SMW BBN 600-275 | Ø381 (15”) | Ø610m (24”) | Manual 3-jaw Ø740 | Ø381 (15”) | |

| Cutting Capacity - Chuck size (mm) | - | Rear: Manual 4-jaw Ø600 | Rear: Manual 4-jaw Ø600 | - | - | - | |

| Cutting Capacity - Bar capacity (mm) | Ø139 | Ø255 | Ø116 | Ø139 | Ø204 | Ø116 | |

| Spindle - Spindle nose | A2-15 | A2-15 | A2-11 | A2-15 | A2-15 | A2-11 | |

| Spindle - Spindle bore (mm) | Ø152 | Ø255 | Ø132.5 | Ø152 | Ø235 | Ø132.5 | |

| Spindle - Transmission type | Auto 4-speed gearbox | Auto 4-speed gearbox | Auto 4-speed gearbox | Auto 4-speed gearbox | Auto 4-speed gearbox | Auto 4-speed gearbox | |

| Spindle - Spindlespeed (rpm) | 1500 | 600 | 2000 | 1400 | 500 | 2000 | |

| Spindle - Spindle motor (kW) | 30/37 | 30/37 | 37/45 | 37/44.4 | 30/37 | 22/26 | |

| Milling/turning spindle with B-axis Spindle bearing diameter (mm) | Ø200 | Ø305 | Ø180 | Ø200 | Ø280 | Ø180 | |

| Milling/turning spindle with B-axis Spindle taper | HSK-A100 | HSK-A100 | HSK-A100 | CAPTO C8 | HSK-A100 | CAPTO C8 | |

| Milling/turning spindle with B-axis Spindle motor (kW) | 38/62 | 38/62 | 38/62 | 38/62 | 38/62 | 38/62 | |

| Milling/turning spindle with B-axis Spindle torque (Nm) | 252/411 | 252/411 | 252/411 | 252/411 | 252/411 | 252/411 | |

| Milling/turning spindle with B-axis Spindle speed (rpm) | 6000 | 6000 | 6000 | 6000 | 6000 | 6000 | |

| Milling/turning spindle with B-axis travel | -110°~+90° | -110°~+90° | -110°~+90° | -110°~+90° | -110°~+90° | -110°~+90° | |

| Milling/turning spindle with B-axis positioning Locking by indexing | Every 5° (std.) 2.5° (opt.) | Every 5° (std.) 2.5° (opt.) | Every 5° (std.) 2.5° (opt.) | Every 5° (std.) 2.5° (opt.) | Every 5° (std.) 2.5° (opt.) | Every 5° (std.) 2.5° (opt.) | |

| Milling/turning spindle with B-axis positioning Locking by hydraulic brake | Free Angle 0.001° | Free Angle 0.001° | Free Angle 0.001° | Free Angle 0.001° | Free Angle 0.001° | Free Angle 0.001° | |

| C-axis Min. axis resolution | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° | 0.001° | |

| ATC-Number of tools | 24 | 40 | 60 | 80 | 40 | 80 | |

| ATC-Max. tool diameter with adjacent tools (mm) | Ø125 | Ø125 | Ø125 | Ø125 | Ø125 | Ø125 | |

| ATC-Max. tool diameter without adjacent tools (mm) | Ø200 | Ø200 | Ø200 | Ø200 | Ø200 | Ø200 | |

| ATC-Max. tool weight (kg) | 15 | 15 | 15 | 15 | 15 | 15 | |

| ATC-Max. tool length (mm) | 400 | 400 | 400 | 450 | 450 | 400 | |

| Axis travel X-axis (mm) | +741/-85 | +741/-85 | +761/-10 | +771/-10 | +836/-10 | +811/-10 | |

| Axis travel Y-axis (mm) | ±100 | ±100 | ±100 | -80/+120 | ±100 | ±100 | |

| Axis travel Z-axis (mm) | 1200 | 4000 | 10000 | 2000 | 3050 | 4000 | |

| Axis travel Rapid traverse (X/Y/Z) (m/min.) | 10/10/10 | 10/10/10 | 10/10/10 | 10/2.3/12 | 10/2.3/12 | 10/2.3/12 | |

| Tailstock - Tailstock travel (mm) | 900 | 3700 | 9700 | 1700 | 2800 | 3600 | |

| Tailstock - Tailstock quill travel (mm) | 150 | 150 | 150 | 150 | 150 | 150 | |

| Tailstock - Quill diameter (mm) | Ø200 | Ø200 | Ø200 | Ø200 | Ø200 | Ø200 | |

| Tailstock - Quill taper | MT#7 | MT#7 | MT#6 | MT#7 | MT#7 | MT#7 | |

| Power - X-axis servo motor (kW) | 7 | 7 | 7 | 7.7 | 7 | 7 | |

| Power - Y-axis servo motor (kW) | 4 | 4 | 4 | 4.3 | 4 | 4 | |

| Power - Z-axis servo motor (kW) | 9 | 9 | 9 | 7.7 | 9 | 9 | |

| Power - B-axis servo motor (kW) | 3 | 3 | 3 | 3.3 | 3 | 3 | |

| Machine weight (kg) | 15000 | 26700 | 63000 | 45000 | 55000 | 55000 | |

| Bed inclination (degrees) | 60° | 60° | 60° | 60° | 60° | 60° | |

| Machine dimensions (L x W x H) (mm) | 5532x2270x2765 | 11200x4800x4100 | 16275x4710x3600 | 9000x5789x4839 | 10632x5789x4839 | 12041x5980x4813 | |

All the specifications above are subject to change without prior notice.

Standard Accessories:

- Fanuc 31-TB PLUS or Siemens SINUMERIK ONE with 15” color screen display

- 4+1 axis machining package

- Ø1200 mm max. swing over bed

- Ø800 mm max. turning diameter

- Belt-type gearbox for heavy-duty cutting

- 3-jaw hydraulic through-hole chuck with 1 set of hard and soft jaws

- Milling / turning spindle HSK-A100 with 0.001° B-axis

- Programmable hydraulic tailstock with rotary quill

- Chain type chip conveyor with trolley

- Auto centralized lubrication system with alarms for guideways and ball screws

- LED working lights

- 3-color signal tower

- Toolbox for basic maintenance

- 1 complete set of machine manuals in English

- 40-tool ATC

- Full enclosure with interlocks system

- External coolant supply system 4 bar

- Coolant gun

- Air gun

- Foot pedals for chuck clamping

Optional Accessories:

- Simultaneous 5-axis machining package

- Twin-chuck system

- CAPTO C8 for milling / turning spindle and ATC

- Sub-spindle or counter-spindle in replacement of tailstock

- Bigger spindle bores like Ø234, Ø318, Ø410, Ø510 mm or even greater

- Z-axis travel with 1500, 2000, 2500, 3000 mm or up to 10000 mm are all available

- Manual or hydraulic self-centering steady rests with manual or automatic travelling system

- Boring bar holder mounted on turret carriage or completely independent boring bar system

- Dented space on headstock sheet metal for boring bar clearance

- Flood coolant (upper washing ramps)

- ATC systems with 60, 80, 100 or above tools are available

- Auto tool touch probe Renishaw HPMA

- Workpiece measuring device Renishaw RMP60

- High pressure coolant system through spindle 20 bar or 70 bar with cartridge type filtration system

- Paper filtration system

- Oil skimmer